Prioritize Small-Scale Manufacturing in USA

04/17/2025

By Ilana Preuss

Makers of everything from food to hardware to components for bigger companies need a boost, which better state and local policies could provide.

Our on-again, off-again trade wars have an underlying theme: that tariffs on imports will boost domestic manufacturing. The assumption is that more United States-based large-scale manufacturing, like auto plants, will quickly scale up, but that kind of manufacturing takes years to plan and build, and economic uncertainty undercuts the potential. The far greater opportunity lies in small-scale manufacturing, which can ramp up quickly and broadly, as it did in response to COVID-19 supply-chain disruptions. Prioritizing small-scale manufacturing with specific initiatives should be a national priority.

Much of the sweeping tariff regime that President Donald Trump announced on April 2 is now on hold, and at this writing it’s impossible to predict how things might play out in the months to come. But when those tariffs were announced, the White House emphasized that “increasing domestic manufacturing is critical to United States national security” and underscored the importance of large-scale manufacturing, saying that “the need to maintain a resilient domestic manufacturing capacity is particularly acute in advanced sectors like autos, shipbuilding, pharmaceuticals, transport equipment, technology products, machine tools, and basic and fabricated metals.” Much of the sweeping tariff regime that President Donald Trump announced on April 2 is now on hold, and at this writing it’s impossible to predict how things might play out in the months to come. But when those tariffs were announced, the White House emphasized that “increasing domestic manufacturing is critical to United States national security” and underscored the importance of large-scale manufacturing, saying that “the need to maintain a resilient domestic manufacturing capacity is particularly acute in advanced sectors like autos, shipbuilding, pharmaceuticals, transport equipment, technology products, machine tools, and basic and fabricated metals.”That focus on large-scale production is to be expected, but it overlooks the vital importance of small-scale manufacturing on many levels. It’s small-scale manufacturers that can adapt quickly to meet short-term needs by applying their skills and expertise to new requirements.

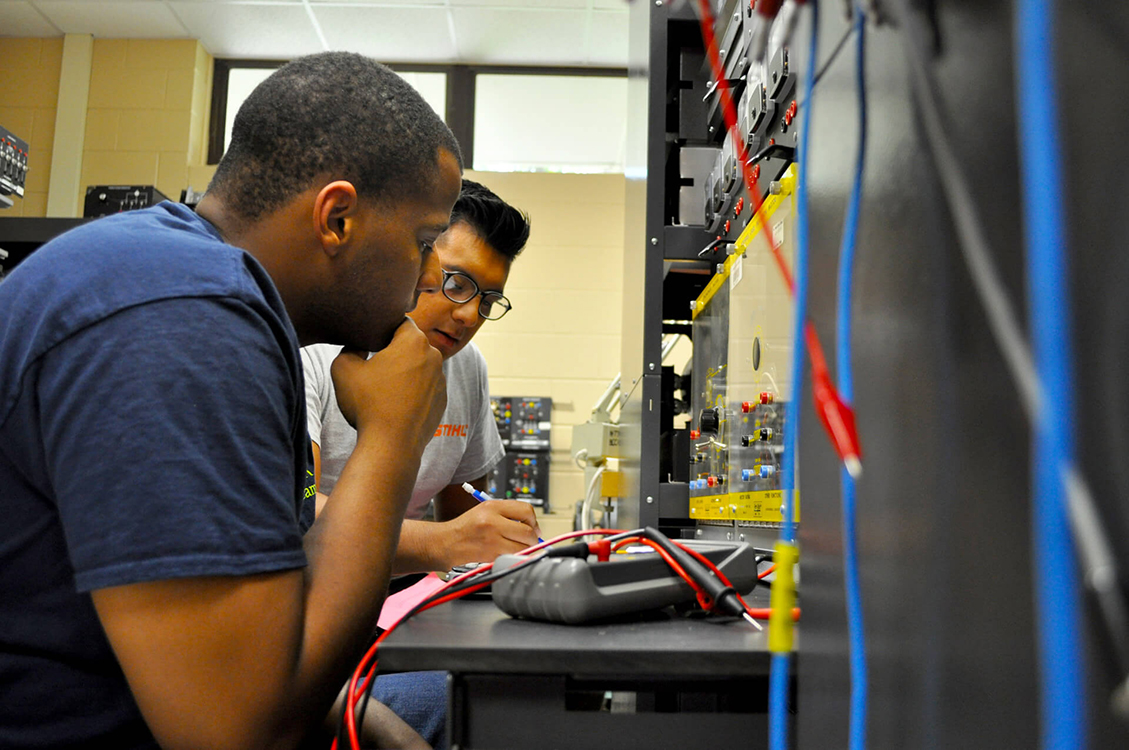

Small-scale manufacturing businesses create products—from artisan crafts to food to hardware and components for advanced manufacturing—that are sold both to consumers and to larger businesses. Since these companies can emerge from the talents and heritage of any community, they can arise anywhere, not just in communities that can attract major production facilities. Benefits spread broadly.

Small-scale manufacturers are also nimble. Because of their scale, they are able to adapt and adjust quickly, as they did during the pandemic. Nearly overnight, consortiums of small product businesses turned out many thousands of pieces of protective equipment and gear for our frontline workers and our neighbors.

Yet, there are barriers in the way of small-scale manufacturers that must be addressed if the benefits are to be maximized. Those barriers often arise at the state and local levels. One major barrier is zoning and tax laws. Too often, zoning laws relegate small-scale manufacturing to industrial areas, when they are exactly what downtowns and neighborhood business districts need for revitalization. Modern manufacturing fits in well next to other businesses and can help to fill the overwhelming amount of vacant commercial space.

Similarly, federal tax laws often encourage landlords to take vacant property as a business loss, thus incentivizing them to leave storefronts unoccupied. And at the local level, jurisdictions tax new equipment for small manufacturing at different rates, making some communities too expensive for expansion.

Another barrier is inflexible financing. Underwriting for vacant storefronts may prevent reducing rents to secure a tenant or other more creative arrangements. And too often banks’ small-business-loan officials are not familiar with the small-scale manufacturing sector and deny loans because of an implicit bias that this sector is high-risk.

Fortunately, these are barriers that can relatively quickly be changed. Not only can new laws be passed, but also government and businesses can pressure owners of vacant downtown properties to do whatever it takes to not leave those spaces empty. State and local departments of commerce or economic development can create financial incentives to help startups move into vacant storefronts, or to create new loan programs.

Successful rapid expansion of domestic manufacturing also requires more transparent information about contract manufacturing capacity nationwide. Governments at all levels could create and coordinate online platforms that reveal the landscape of local manufacturing—its needs and capacities. They could map out that landscape and network it. Too often, a manufacturer does not know that needed production skills and capacities are available, either nearby or through a regional producer.

These are all relatively easy fixes that can spread the benefits of small-scale manufacturing, providing economic stimulation in communities large and small. For all of the advantages of large-scale manufacturing, it won’t happen everywhere, it will take time to activate, and it will bring jobs to limited locations. Small-scale manufacturing should be prioritized so that all communities can reap the benefits.

Ilana Preuss is the founder and CEO of Recast City and the author of the new book Recast Your City: How to Save Your Downtown with Small-Scale Manufacturing. Previously, she led the technical assistance program at the United States Environmental Protection Agency’s Smart Growth Program and served as the vice president and chief of staff at Smart Growth America. She holds a bachelor’s degree in urban and regional studies from Cornell University and a master’s in city planning from the University of Maryland. She can be reached at ilana@recastcity.com.

Source:Governing

Back To News |

||

|

|

||

|

© 2025 Small Business Exchange, Inc. |

||